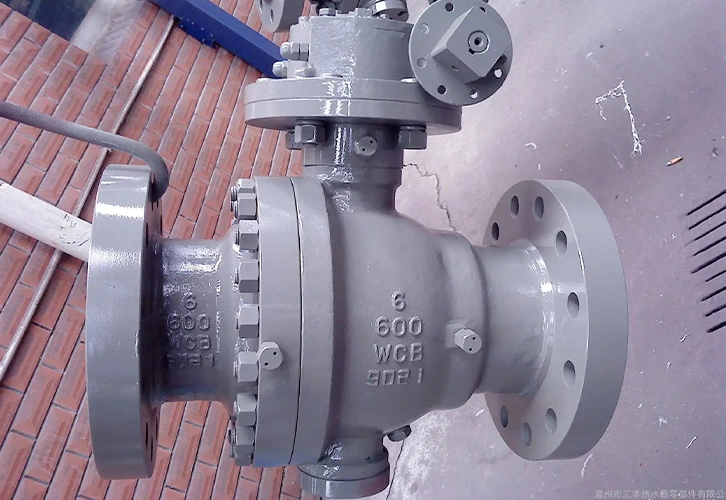

High pressure forged steel ball valve is based on user needs

High-pressure forged steel ball valves are designed according to user needs to meet the requirements of sulfurization application cracking in sulfurization environments. This series of high-pressure forged steel balls are designed, selected, manufactured, tested, surface treated and painted in strict accordance with the NACE standard requirements of the American Association of Corrosion Engineers.

This series of ball valves not only have a wide range of materials, but also the internal materials are all made of nickel-plated 316 material, and the sealing rings are made of special polymer materials. The valves are not only corrosion-resistant, but also have strong anti-sulfurization ability, fireproof, anti-static, and good sealing performance. They have a wide range of operating pressure and temperature, and are available in full-bore and reduced-bore versions. They can also be equipped with a variety of drive devices. They are ideal valves for chemical, petroleum refining, and natural gas extraction and transportation systems. Main functions:

When the medium stagnating in the valve cavity abnormally increases in pressure due to temperature changes, the medium pressure pushes the valve seat away from the ball, achieving the effect of automatic pressure relief. After the pressure is relieved, the valve seat automatically returns to its original position.

In addition to general sealing, the valve seat has a specially designed sealing structure that can serve as an emergency rescue in the event of leakage due to sealing ring damage.

When the valve seat seal ring is burned or softened due to fire or abnormal temperature, the valve can still operate reliably. At the same time, the valve seat and the ball form a metal-to-metal seal to achieve a temporary seal, preventing the fire from spreading further, which complies with the provisions of AP16FA.

Unscrewing the drain device can check whether the valve seat is leaking, and can also discharge the retained matter in the middle cavity to reduce the contamination of the medium on one side of the valve. In the working state, when the valve is fully open or fully closed, the valve stem stuffing box can be replaced.

The valve stem is sealed with PTFE packing and O-ring, which is especially suitable for gas medium. The moving part of the valve stem adopts high-quality SF self-lubricating bearings to reduce the friction coefficient and reduce the operating torque.