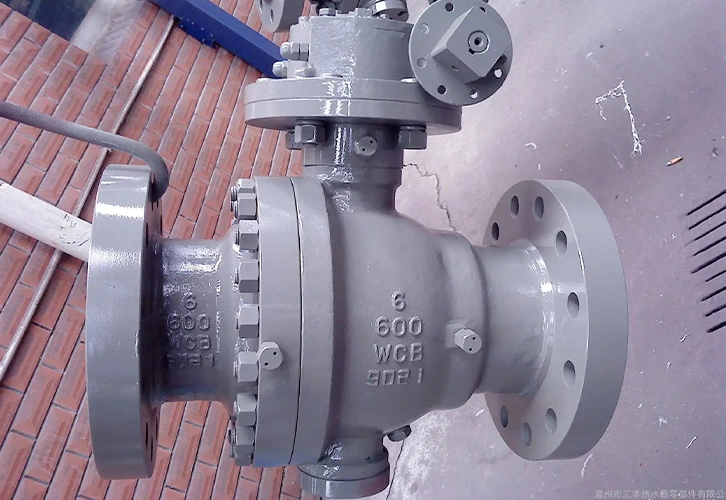

Main performance specifications for forged steel ball valves

The three-piece connection forged steel fixed ball valve is a valve body that is divided into three parts along the cross section perpendicular to the axis of the valve channel at the two valve seats. The entire valve is symmetrical along the central axis of the valve stem. It is mainly used to cut off, distribute and change the flow direction of the medium on the pipeline. Its large pivot structure ensures the accurate center position of the ball under high pressure, ensuring the good operating performance of the valve; the standard valve seat adopts a spring structure to push the valve seat toward the ball, ensuring good inlet and outlet bidirectional sealing performance; using the built-in discharge valve, the middle cavity of the valve body can be discharged outward; the pivot adopts an anti-blowout protection structure to effectively prevent leakage; the low friction coefficient bearing reduces the torque to a minimum, which is convenient for the opening and closing of the valve; the valve stem and the valve body are in effective contact, so that the anti-static grounding device has excellent performance. It has the advantages of excellent performance, high reliability, wide application and reasonable price. It is suitable for: chemical, petroleum, natural gas, metallurgy and other industries and natural gas long-distance pipelines containing hydrogen sulfide media, many impurities and severe corrosion.

1. Main performance specifications

|

Test pressure (Mpa)

|

Nominal pressure (Mpa)

|

Pressure level (Class)

|

|||||||||||

|

1.6

|

2.5

|

4.0

|

6.4

|

10.0

|

16.0

|

25.0

|

150

|

300

|

400

|

600

|

900

|

1500

|

|

|

Strength test

|

2.4

|

3.8

|

6.0

|

9.6

|

15.0

|

24

|

37.5

|

3.1

|

7.8

|

10.2

|

15.3

|

23.1

|

38.4

|

|

Sealing test

|

1.8

|

2.8

|

4.4

|

7.0

|

11.0

|

17.6

|

27.5

|

2.2

|

5.6

|

7.5

|

11.2

|

16.8

|

28.1

|

|

Airtightness test

|

0.5-0.7

|

||||||||||||

|

Operating temperature

|

PTEE≤150℃ PPL E≤300℃ Carbon fiber≤350℃

|

||||||||||||

|

Applicable media

|

C: Water, oil, steam P: Nitric acid (temperature ≤ 200°C) R: Acetic acid (temperature ≤ 200°C)

|

||||||||||||

2.Material of main parts

|

Parts Name

|

Material

|

|||

|

Material code

|

C

|

L

|

P

|

R

|

|

Valve body and bonnet

|

WCB

|

ZGOOCr17Ni14Mo2(CF3M)

|

ZG1Cr18Ni9Ti(CF8)

|

ZG1Cr18Ni12Mo2Ti(CF8M)

|

|

sphere

|

2Cr13

|

ZGOOCr17Ni14Mo2(CF3M)

|

ZG1Cr18Ni9Ti(CF8)

|

ZG1Cr18Ni12Mo2Ti(CF8M)

|

|

Valve stem

|

2Cr13

|

316L

|

1Cr18Ni9Ti(304)

|

1Cr18Ni12Mo2Ti(316)

|

|

Seat sealing surface

|

PTFE, carbon fiber + PTFE, para-polystyrene

|

|||

|

Stud Nuts

|

35 35CrMoA(B7) 45(2H)

|

2Cr13(420) 1Cr18Ni9 1Cr17Ni2(431)

|

||

|

filler

|

V-type PTFE, flexible graphite

|

|||