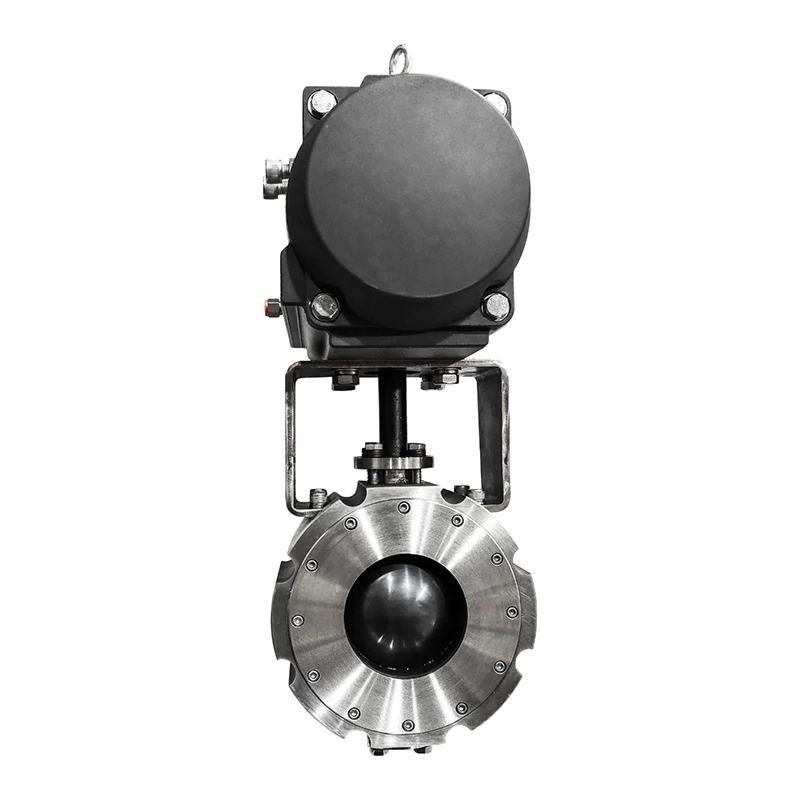

Forged Steel Ball Valve

Overview This ball valve features trunnion mounted configuration, which has two-piece and three-piece valve body structures. The body and bonnet are c

- Structure

- Trunnion Mounted

- Function

- Cut-off

- Standard

- API-ISO-En-JIS

- Specification

- 18′′ (DN450, 450MM)

- Driving Mode

- Pneumatic

- Channel

- Full Bore

- Type

- Quarter Turn Ball Valve

- Temperature

- Normal Temperature

Overview

This ball valve features trunnion mounted configuration, which has two-piece and three-piece valve body structures. The body and bonnet are connected by bolts, and the seal adopts reinforced PTFE embedded in the stainless steel ring. It is suitable for long-distance pipelines and general industrial pipelines. Due to its strength and safety, it is suitable for various corrosive and non-corrosive media.

Compared with the floating ball valve, during working, the force generated by the fluid pressure in front of the valve on the ball is all transmitted to the bearing, and the ball will not move to the valve seat, so the valve seat will not bear excessive pressure, so the sealing performance is stable and the service life is long.

Features

1. Labor-saving operation:

The ball is supported by the upper and lower bearings to reduce friction and eliminate the excessive torque caused by the huge sealing load formed by the imported pressure pushing the ball and the sealing seat.

2. Reliable sealing performance:

PTFE unisexual material sealing ring is embedded in the stainless steel valve seat, and the end of the metal valve seat is equipped with a spring to ensure sufficient pre-tightening force of the sealing ring. When the sealing surface of the valve is worn during use, it will be under the action of the spring. The valve continues to ensure good sealing performance.

3. Fire protection structure:

In order to prevent the PTFE sealing ring from burning due to sudden heat or fire, causing a large leak, which will encourage the fire, a fireproof sealing ring is set between the ball and the valve seat. When the sealing ring is burned, Under the action of the spring force, the valve seat sealing ring is quickly pushed to the ball to form a metal-to-metal seal, which has a certain degree of sealing effect. The fire resistance test meets the requirements of AP16FA and API607 standards.

4. Automatic pressure relief function:

When the pressure of the stagnant medium in the valve cavity rises abnormally and exceeds the pre-load of the spring, the valve seat retreats away from the sphere to achieve the effect of automatic pressure relief. After the pressure is relieved, the valve seat automatically recovers.

5. Self-Drainage:

Drain holes are set up and down the valve body to check whether the valve seat is leaking. During work, when the valve is fully open or fully closed, the pressure in the middle cavity can be removed, and the packing can be directly replaced; the middle cavity can be discharged. Retentate, reduce the pollution of the medium to the valve.

Scope

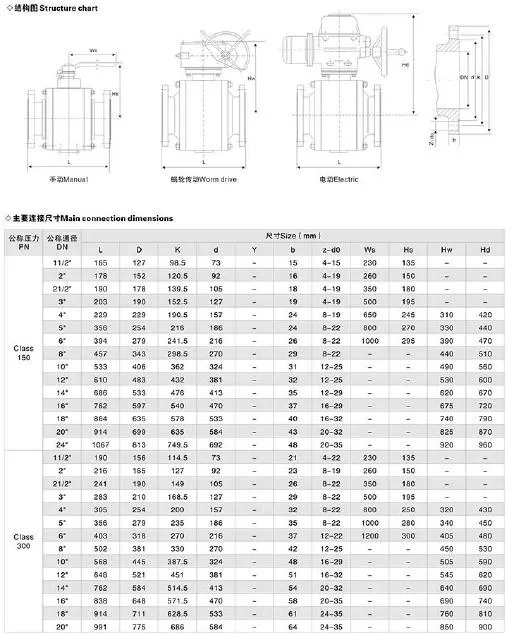

| Nominal size | 2"~24"(DN25~DN1200) |

| Nominal pressure | Class 150~Class 2500(PN10~PN420) |

| Standard: | ASME B16.34, API6D, ISO17292 |

| Body material | Carbon steel, Stainless steel, Alloy steel, Duplex stainless steel |

| End connection | RF, BW, RTJ, |

| Operation | Manual, Pneumatic, Electric, Hydraulic |

Product Parameters