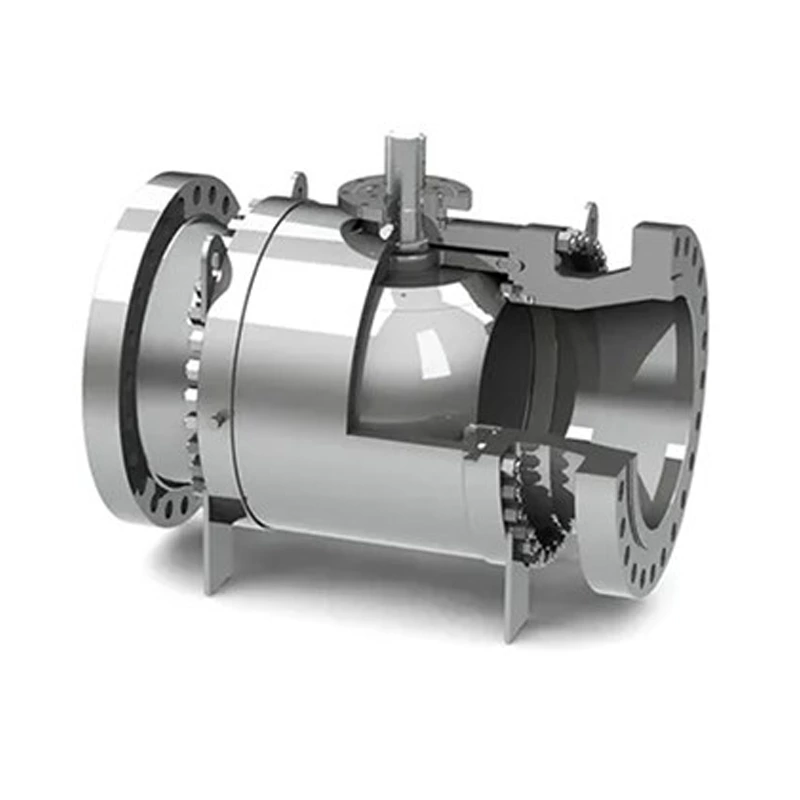

High Temperature Metal Seated Ball Valves

Application The Side Entry Trunnion Mounted Ball Valve is suitable for a wide range of industrial applications, including: Oil and gas production: The

- Structure

- Trunnion Ball Valve

- Standard

- API 6D

- Specification

- 2"-60"

- Driving Mode

- Worm Gear

- Channel

- Straight Through Type

- Type

- Trunnion Ball Valve

- Application

- Industrial Usage, Water Industrial Usage

Application

The Side Entry Trunnion Mounted Ball Valve is suitable for a wide range of industrial applications, including:

- Oil and gas production: The valve's high pressure and high temperature capability make it suitable for use in the oil and gas industry, where it can be used to control the flow of liquids, gases, and other fluids in pipelines and other production systems.

- Chemical processing: The valve's durability and resistance to corrosion make it suitable for use in chemical processing plants, where it can be used to control the flow of corrosive fluids and chemicals.

- Power generation: The valve can be used in power generation plants, such as coal, gas and nuclear power plants, where it can be used to control the flow of steam, water, and other fluids.

- Refineries: This valves are widely used in refining process such as fluid catalytic cracking, fluid coking, visbreaking, and catalytic reforming.

- Water treatment: The valve can be used in water treatment plants, where it can be used to control the flow of water and other liquids in the treatment process.

- Pulp and paper industry: The valve is often used in pulp and paper mills, where it is used to control the flow of liquids and other materials used in the production process.

- Other industrial applications: The valve is also suitable for use in other industrial applications such as mining, food and beverage processing, and many other heavy industry applications.

Range of Materials

Standard body/bonnet materials include nine grades of carbon, low alloy and stainless steel, for special applications they can be supplied in other grades of ally and stainless steel, there's a full range of trim materials to match any service optional packing and gasket materials are available for a full range of service conditions.

Applicable Standards

- STEEL BALL VALVES API 608/API 6D

- STEEL BALL VALVES ISO 14313

- FIRE SAFE,API 607

- ANTI STATICS,API 608

- STEEL VALVES,ASME B16.34

- FACE TO FACE ASME B16.10

- END FLANGES,ASME B16.5

- BUTTWELDING ENDS ASME B16.25

- INSPECTION AND TEST, API 598/ API 6D

Design descriptions

- FULL PORT DESIGN

- BB.BOLTED BONNET.SPLIT BODY

- THREE PIECES BODY FOR 12″ & ABOVE

- TRUNNION MOUNTED BALL TYPE

- BLOW-OUT PROOF STEM

- FIRE SAFE CONSTRUCTION

- ANTI STATICS DEVICE

- STOPPER DEVICE

- ISO 5211 MOUNTING PAD

- FLANGED OR BUTTWELDING ENDS

- AVAILABLE WITH WG OPERATOR

Product Parameters

| Part Names | Part Materials | ||||||

| Body | WCB/A105 | LCB/LF2 | WC6/F22 | CF8/F304 | CF8M/F316 | CF3/F304L | CF3M/F316L |

| Bonnet | WCB/A105 | LCB/LF2 | WC6/F22 | CF8/F304 | CF8M/F316 | CF3/F304L | CF3M/F316L |

| Ball | A105+ENP | SS304 | F22 | SS304 | SS316 | SS304L | SS316L |

| Stem | A105 | F304 | F6a | F304 | F316 | F304L | F316L |

| Seat/Seat Ring | PTFE/RPTFE/NYLON/DEVLON/PEEK or METAL | ||||||

| Packing | Graphite/PTFE | ||||||

| Gasket | SS304+Graphite/SS304+Graphite | ||||||

| Bolts/Nuts | B7/2H | L7/4 | B16/4 | B8/8 | B8M/8M | B8/8 | B8M/8M |

| Suitable Medium | W.O.G etc. | HNO3, CH3OOH etc. | |||||

| Suitable Temperature | -29~425 °C | -46~340 °C | -46~340 °C | -196~427 °C | -196~427 °C | -196~427 °C | -196~427 °C |